In Service for over 45+ yrs

Carl Bradford asks:

"How best to avoid ink drying in with water-based jobs above four colors (The spiral of doom)?"

The onset of these high temperatures in the summer months will always strike fear into screen printers, we work two feet away from a heat source and we frequently add further heat sources to our multi color plastisol jobs.

The water-based printers also face this time of year with great trepidation as the fear of ‘drying in’ starts to manifest.

Water-based ink has a high water content and is designed to cure when this water is removed, usually the H2O is removed from the printing paste in the relatively controlled environment of the tunnel dryer, it is this removal of water that is fundamental in the cross-linking process, but this evaporation process can start to happen in a hot shop also.

The placement of so many heat sources, dryers, flash units and glass windows, close to the open screen which is loaded with water-based ink can speed up the process we call “Dryin’In”, “Blocking”, “Cloggin’” and more descriptive words which are unsuitable for publication.

This phenomena is a large reason that printers stay away from WB inks. Plastisol will stay wet for around 5 years! And the only down side to this is that it transfers to the car, the dog and a small amount of wet plastisol green can always be found on the elbow of unsuspecting press operators. Water-based ink will start to evaporate as soon as we open the lid of the ink bucket.

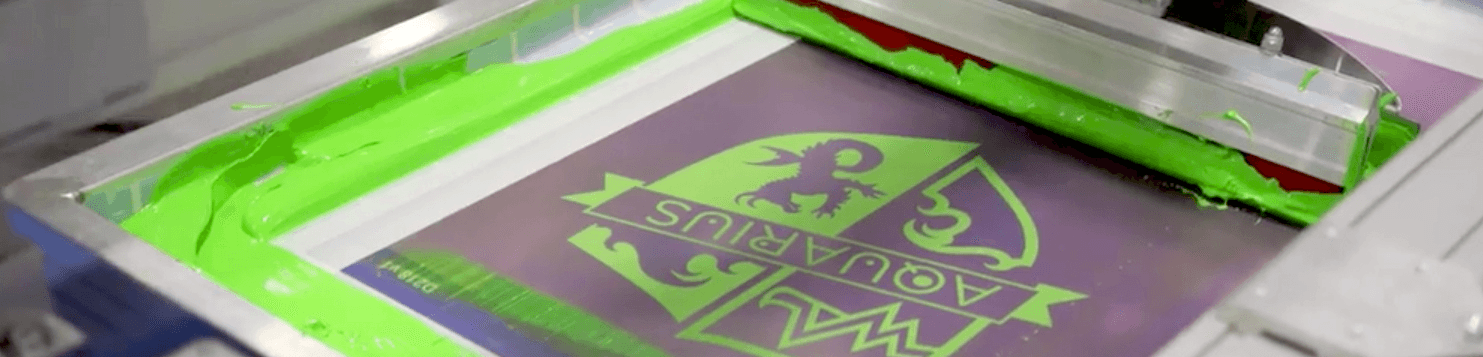

When we spread the ink over the large surface area of a screen, we invite the evaporation process to begin in earnest. The ink starts to dry in the mesh, usually starting in the smallest fine detail areas first. It does a fantastic job of choking the design! In fact it can remove pixels from the edge of a print faster than I can in Photoshop!

How do we stop it?

Basically we have many angles of attack that we can implement to reduce or control this evaporation issue.

Good housekeeping is essential!!

Replacing lids on tubs. This will prevent water from escaping from the ink bucket. This simple task sounds so obvious, but if we are facing the pressure of a tricky job and the heat of a print shop, we can overlook this basic procedure.

Heavy flood technique. Unlike plastisol which we use brute force to force into the holes of the mesh, water-based ink will willingly fall into the same gaps in the mesh with the help of gravity and a soft viscosity, we can set the floodbar slightly higher, this will leave a heavy blanket of ink on the mesh. A good 3mm protective coating of ink will delay the drying in process significantly. The theory is simple, a larger surface area of thick ink will take more time to evaporate than a large area of thin ink.

Control the environment. Although we can’t turn off the heat sources or open windows that don’t exist, we can add more moisture to the room. An easy mistake to make is to introduce a fan, but this will speed up the evaporation process as more air is moved around. A humidifier is the perfect choice here. We can either make a home made one that we stole from the terrarium/vivarium ( the turtles will be fine ! we are using WB inks and we can stop growing ‘organic tomatoes’ for now.)

These humidifiers or foggers are widely available now and range from a plastic box with a fan and a drainpipe to units that are branded to the press. The main use of these units is to replace the lost water back into the environment. A squirty bottle misting with water can also introduce some of that lost moisture.

Ink management. The ink we use for WB is not as robust as the plastisol we love so much and it needs to be maintained as its rheology changes during use, the addition of water and other additives can drastically offset the loss of moisture as we use the ink.

Don’t Panic. This one is important to avoid the spiral of doom. After printing for the last 35 years I still enter this state occasionally, stopping to sort a problem creates more problems which cause more delays which cause more issues, and the spiral is born.

My advice is to stop. Spend 5 minutes cleaning the screens and more importantly drying them, go outside count to ten, pray to the squeegee gods, manifest some snacks or whatever it is that allows you to breathe and relax. Then start again, ensuring we have all the variables under control. Ink is fluid, moisture is under control.

Water-based ink can give fantastic results and when we control the variables we can fully master all its little quirks.

Avoiding the spiral of doom is not always as easy as its seems, but we could always just swap out the ink for plastisol pvc free! Would anyone know? Would anyone care? The print looks good and feels good.

Join Tony at BSP Apparel for the 301 Advanced Screen Printing Seminar in North Salem, New York on November 1. more info

Article written by Tony Palmer, Palmprint

Tony has more than 30 years experience in garment decoration ranging from manual screen printing on hand carousels to the operation of multi-color automatic presses. Specifically Tony is an expert on MHM Automatics, Tesoma, Exile Spyder, Douthitt CTS, Zentner, and numerous manufacturers of textile decorating equipment.

#spsiinc #palmprint #mhmscreenprinting