In Service for over 45+ yrs

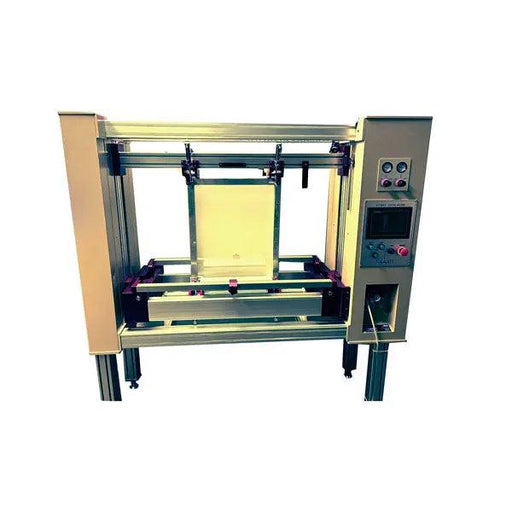

The shop looking to increase the productivity of their screen room, the automatic coaters is a great solution. Consistent screens time after time, day after day.

Sale

Sale

It's time to step up your game. Description Manually coating screens is strenuous, exhausting and often inconsistent. The G-Coat 406s allows your g...

View full details Sale

Sale

SPSI is pleased to offer the Saati Pro Coat SF Textile provides a perfect solution for the small to medium shops that think automatic coating is t...

View full details Sale

Sale

The Saati ProCoat 25x36 Dual Screen Auto Coater is the perfect solution for automating screen coating. This affordable unit provides consistent qu...

View full detailsAmazing color and quality and pick up was very easy with very nice people

Thank you spsi

Great quality paint and easy to use. Black was very black and not faded which was great.

Nozzles and can gum up and clog constantly. A TOTAL hassle. Had to order bigger nozzles as to not waste the product.

Best thread around.